Stage Two dewatering advancing on schedule; approximately 20% complete

Start-up of Africa’s largest copper smelter to commence in early November

During the third quarter, Kamoa-Kakula’s Phase 1, 2, and 3 concentrators milled a total 3.46 million tonnes of ore, producing 71,226 tonnes of copper. Copper production year to date totaled 316,393 tonnes. Production guidance of 370,000 tonnes to 420,000 tonnes of copper in concentrate is maintained, with mining of higher-grade areas on the western side of the Kakula Mine expected from mid-November.

Stage Two dewatering activities are over 20% complete, with underground water levels on the eastern side of the Kakula Mine having declined by over 20 metres since the beginning of September. Stage Two dewatering is expected to be completed by the end of November.

Le lancement de la fonderie est prévu pour début novembre, l’installation d’un onduleur (système d’alimentation sans interruption – ASI) de 60MW étant en voie d’achèvement. L’UPS protégera le complexe de la fonderie contre d’éventuelles coupures de courant pendant la période de montée en puissance.

Founder and Co-Chairman Robert Friedland commented:

“This quarter should mark a turning point in operations, as we anticipate higher grades from Kakula’s western side from next month, with selective mining of the existing workings on the eastern side of Kakula planned from Q1 2026. We’re also on the cusp of starting operations at Africa’s largest and greenest, direct-to-blister copper smelter, which is expected to drive lower cash costs as we complete its ramp-up.

In preparation for the heat-up of Kamoa-Kakula’s state-of-the-art, 500,000-tonne-per-annum, direct-to-blister copper smelter, an operator oversees a training exercise on the slag cleaning furnace blister ladles.

Summary of quarterly production data from Kamoa-Kakula

| Q3 2024 | Q4 2024 | Q1 2025 | Q2 2025 | Q3 2025 | |

| Phase 1 & 2 | |||||

| Ore tonnes milled (000’s tonnes) | 2,215 | 2,329 | 2,211 | 1,991* | 1,838 |

| Feed grade of ore processed (% copper) | 4.86% | 5.08% | 5.01% | 4.12%* | 2.50% |

| Copper recovery (%) | 86.6% | 87.0% | 88.3% | 85.4%* | 81.3% |

| Copper in concentrate produced (tonnes) | 94,214 | 102,042 | 97,575 | 71,401* | 37,744 |

| Phase 3 | |||||

| Ore tonnes milled (000’s tonnes) | 1,050 | 1,326 | 1,512 | 1,631 | 1,618 |

| Feed grade of ore processed (% copper) | 2.64% | 2.82% | 2.76% | 2.92% | 2.44% |

| Copper recovery (%) | 79.9% | 85.1% | 85.1% | 85.5% | 84.2% |

| Copper in concentrate produced (tonnes) | 22,099 | 31,777 | 35,545 | 40,608 | 33,522 |

| Combined Phase 1, 2, and 3 | |||||

| Ore tonnes milled (000’s tonnes) | 3,266 | 3,655 | 3,723 | 3,622 | 3,456 |

| Feed grade of ore processed (% copper) | 4.14% | 4.26% | 4.10% | 3.58% | 2.47% |

| Copper recovery (%) | 85.3% | 86.6% | 87.4% | 85.4% | 82.7% |

| Copper in concentrate produced (tonnes) | 116,313 | 133,819 | 133,120 | 112,009 | 71,266 |

Data in red denotes a quarterly record

*Phase 1 & 2 production was impacted in the second quarter by seismic activity at the Kakula Mine as announced on May 20, 2025.

Kakula head grades to improve in Q4 2025 as dewatering activities open up higher-grade mining areas

During the third quarter, the Phase 1, 2, and 3 concentrators milled 3.46 million tonnes of ore, producing 71,226 tonnes of copper. Total copper production year to date is 316,393 tonnes.

As announced on June 11, 2025, mining operations on the western side of the Kakula Mine restarted on June 7, 2025. Since mid-June, the mining rate has increased to an average rate of 350,000 tonnes per month (4.2 million tonnes on an annualized basis). To assist with the increase in the mining rates from the western side of the Kakula Mine, the cut-off grade has been lowered to 1.5% copper (previously 2.0%).

Mining on the western side of the Kakula Mine has been focused on higher-elevation areas in the north and southwest, where copper grades are lower than those of the higher-grade centre, which is currently submerged. From mid-November, mining crews plan to advance towards the centre of the western side of the Kakula Mine, improving head grades to between 3.5% and 4.5%.

The Phase 1 and 2 concentrators will continue to process ore from the western side of the Kakula Mine, as well as surface stockpiles, until Q1 2026, when the stockpiles are depleted. Thereafter, selective mining will commence within the existing workings on the eastern side of the Kakula Mine, which will augment rising production from higher-grade areas on Kakula’s western side to underpin improved underground mining rates.

The Phase 3 concentrator milled 1.62 million tonnes of ore in the third quarter, producing 33,522 tonnes of copper. For a second consecutive quarter, the Phase 3 concentrator averaged a milling rate equivalent to 6.5 million tonnes annualized, which is 30% higher than design capacity of 5.0 million tonnes per annum. The average quarterly feed grade for the Phase 3 concentrator was 2.44% copper. The cut-off grade was also lowered to 1.5% copper at the Kamoa Mine to achieve higher mining rates, providing sufficient feed for the Phase 3 concentrator and supplementary feed for the Phase 1 and 2 concentrators. For the foreseeable future, it is expected that the feed grade into the Phase 3 concentrator will continue to average approximately 2.5% copper.

Stage Two dewatering of the Kakula Mine is advancing to plan at over 20% complete

The four Stage Two high-capacity submersible pumps were commissioned over the course of two weeks between the end of August and mid-September. The four pumps are operating at the total design rate of approximately 2,600 litres per second. Including the mobile Stage One pump stations located underground, the total pumping rate at the Kakula Mine, has the potential to pump up to 6,400 litres per second, or 550 megalitres per day, subject to available underground access.

Stage Two dewatering of the Kakula Mine is over 20% complete and is expected to be completed by the end of November 2025, at which point the underground water level is anticipated to be near the bottom of the Stage Two dewatering shafts.

To date, approximately 13 kilometres of lateral development has been rehabilitated. As the water level declines, the mining crews are primarily focused on rehabilitating the access drives required for repositioning the Stage One underground pumping infrastructure, as well as the access towards the Stage Three pump stations, which are currently submerged.

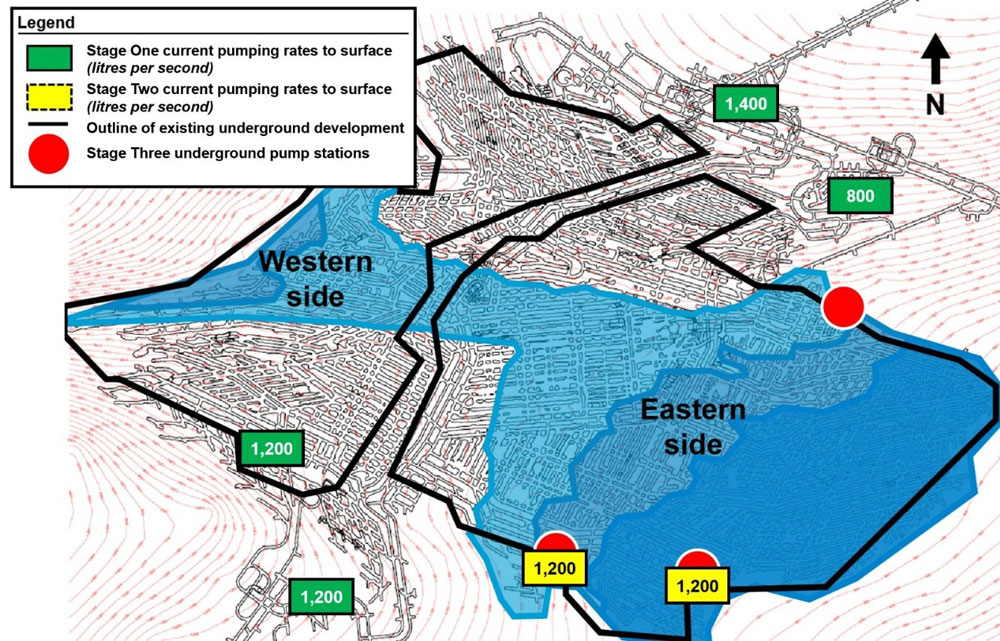

Stage Three pumping will complete the remaining dewatering below the water level accessible by the Stage Two high-capacity submersible pumps, as shown in Figure 1. The mining crews expect to start gaining access to the existing Stage Three pumping infrastructure from November. Each pump station will be refitted and recommissioned with new pump motors and associated electrical infrastructure. Stage Three pumping is expected to be complete in Q1 2026.

Aerial view looking south over the two adjacent sites where the four Stage Two high-capacity, submersible pumps were installed, in pairs, at the bottom of two existing 400-metre deep shafts.

Figure 1. A schematic of the projected decrease in underground water levels at the Kakula Mine from the end of September (light blue) to the end of November 2025 (dark blue). Dewatering of the entire Kakula mine is expected to be completed in February 2026.

Water pumped out from the Kakula Mine is fed into nearby settling ponds. Stage Two dewatering of the Kakula Mine is expected to be complete at the end of November 2025.

The two sites where the Stage Two dewatering infrastructure is located. Both sites were established, with all pumping infrastructure installed and commissioned within just 6 weeks.

Mine planning and scheduling is well advanced to support the ramp-up of underground mining activities from both the Kakula and Kamoa mines, with a medium-term target of returning the milling rate to 17 million tonnes per year, and ultimately targeting annualized copper production of over 550,000 tonnes

Copper production guidance for 2026 and 2027 will be released once sufficient physical inspection of the newly dewatered areas of the Kakula Mine has been completed. The new life-of-mine plan is expected to be released in Q1 2026.

Smelter start-up scheduled for early November; installation nearing completion of 60-megawatt, battery-powered, uninterruptible power supply facility

Heat-up of Kamoa-Kakula’s on-site, direct-to-blister copper smelter is expected to commence in early November 2025. Kamoa-Kakula’s management team expects to prioritize the processing of all concentrates produced by the Phase 1, 2, and 3 concentrators through the on-site smelter, with any excess concentrate continuing to be toll-treated at the nearby Lualaba Copper Smelter (LCS), in Kolwezi.

The smelter start-up will commence as the installation of the uninterruptible power supply (UPS) facility nears completion later this month. The 60 MW UPS is designed to provide up to 2 hours of instantaneous back-up power to the smelter, protecting the operation from voltage fluctuations in the DRC grid. In addition to the UPS, there is a further 60 MW of dedicated diesel-powered, back-up generator capacity.

There is sufficient on-site copper concentrate inventory for the smelter start-up in early November. As of September 30, 2025, Kamoa-Kakula’s unsold copper in concentrate inventory totaled 59,000 tonnes, which includes 7,300 tonnes located at LCS. The first feed of concentrate into the smelter is expected approximately four to six weeks after heat-up commences.

Members of the smelter team are inspecting the sulphuric acid plant ahead of the furnace heat-up. The smelter is expected to produce up to 700,000 tonnes per annum of high-strength sulphuric acid, which is in high demand across the Central African Copperbelt.