Underground water levels in Kakula Mine stabilized; dewatering to commence in Q3 2025

Kamoa Copper revises 2025 production guidance to between 370,000 and 420,000 tonnes of copper

Smelter start-up expected to commence in September 2025, with first anode anticipated in October 2025

KOLWEZI, DEMOCRATIC REPUBLIC OF THE CONGO – Kamoa Copper announce today an update on operational activities at the Kamoa-Kakula Copper Complex, including preliminary geotechnical findings relating to underground seismic activity experienced at the Kakula Mine, as first announced on May 20, 2025

Underground mining on the western side of the Kakula Mine has resumed in a safe and conservative manner, with equipment and mining crews returning underground on June 7, 2025. The short-term mine plan for the western side of Kakula has been updated to include recommendations from the preliminary findings.

Mining activities in the eastern side of the Kakula Mine are expected to start imminently, with activities solely focused on developing access drives to a new mining area east of the existing mine workings. Development to the new mining area will be isolated from the dewatering activities on the same side of the mine.

As announced on June 2, 2025, additional underground pumping capacity was installed at the Kakula Mine, stabilizing underground water levels. The frequency of seismic activity has decreased since first reported on May 18, 2025. Dewatering the eastern side of the Kakula Mine is expected to commence in August 2025 and be complete during the fourth quarter.

Recommendations from the preliminary geotechnical findings from world-leading experts have been included in the short-term mine plans for the Kakula Mine to ensure a safe restart of underground operations. Concurrently, medium- and longterm mine plans are under review by Kamoa-Kakula management, together with technical consultants.

The Phase 1 and 2 concentrators continue to operate at approximately 50% of their combined operating capacity, processing ore from surface stockpiles. The processing rate of the concentrators will ramp up throughout the remainder of 2025, as mining on the western side of the Kakula Mine increases, supplemented by feed from ore stockpiles. Mining operations at the

Kamoa underground mine, as well as ore processing at the adjacent Phase 3 concentrator, continue to outperform.

With the necessary copper concentrate expected to be available, the on-site copper smelter is anticipated to start up in September, with first anode expected in October 2025.

Ivanhoe Mines Executive Co-Chair, Robert Friedland commented:

“We are thankful and deeply appreciate our team’s swift response to stabilize underground water levels in the Kakula Mine and resume mining on the western side. The team has quickly secured the critical equipment needed to safely dewater the entirety of the mine, while preparing to access a new high-grade mining area in the east.

“While it’s still too early to outline our detailed plans for 2026 and 2027, the future remains bright across the Kamoa-Kakula Copper Complex and adjacent Western Forelands Exploration Project. Kamoa-Kakula is, and will continue to be, a worldclass Tier One operation, with decades ahead of us as one of the world’s leading copper producers.”

President & Chief Executive Officer, Marna Cloete, commented:

“We are working tirelessly to safely and systematically restore full operations at the Kakula Mine. Safety has always been, and will always remain, our highest priority. We want to extend our sincere thanks to the mining crews, the engineering teams and our long-term contractors for their extraordinary efforts in restoring pumping capacity and restarting operations, all without any lost time injuries.

“The resilience of our team and the strength of our operations reflect the extraordinary nature of this world-class copper district—and the future it holds for generations to come.”

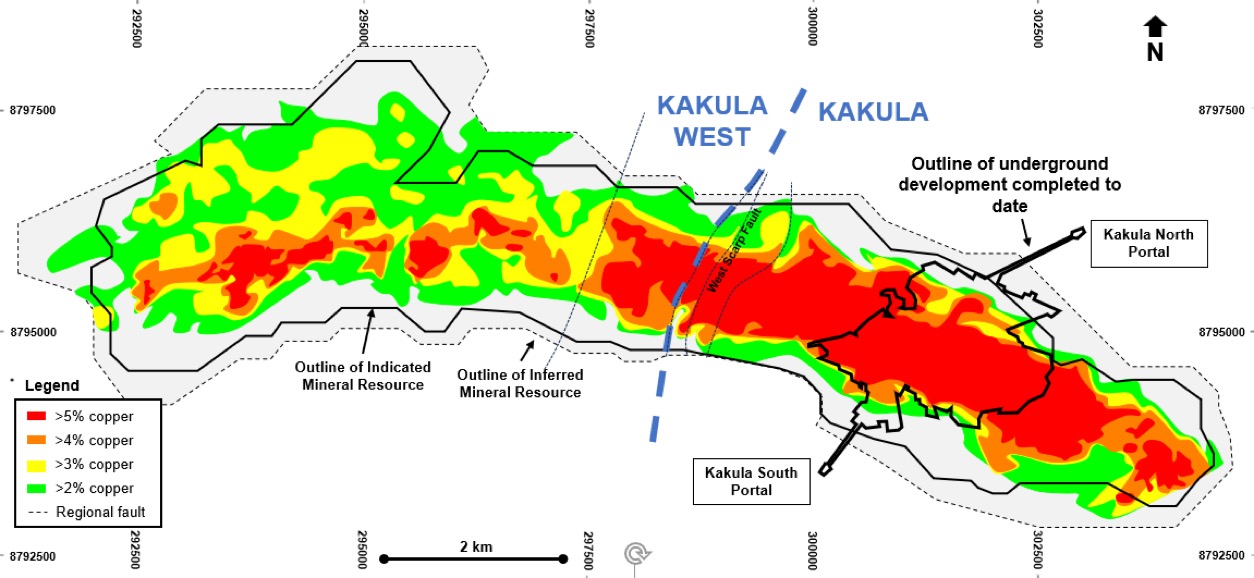

Figure 1. Outline of the Kakula and Kakula West orebody, overlaid with the underground development since mining commenced in 2021. A significant portion of the original Kakula deposit remains unmined as of May 2025.

Notes: Existing underground development as at May 2025.

Illustration is based on the 2023 Kamoa-Kakula IDP showing the estimated average grade of each vertical stack of blocks above a 2% total copper cut-off. A minimum 3-metre thickness is applied.

Underground water levels in Kakula Mine have stabilized; underground mining recommences on the western side of Kakula

Although water inflow rates into the Kakula Mine modestly increased following the initial seismic activity, they have since stabilized at approximately 4,000 litres per second.

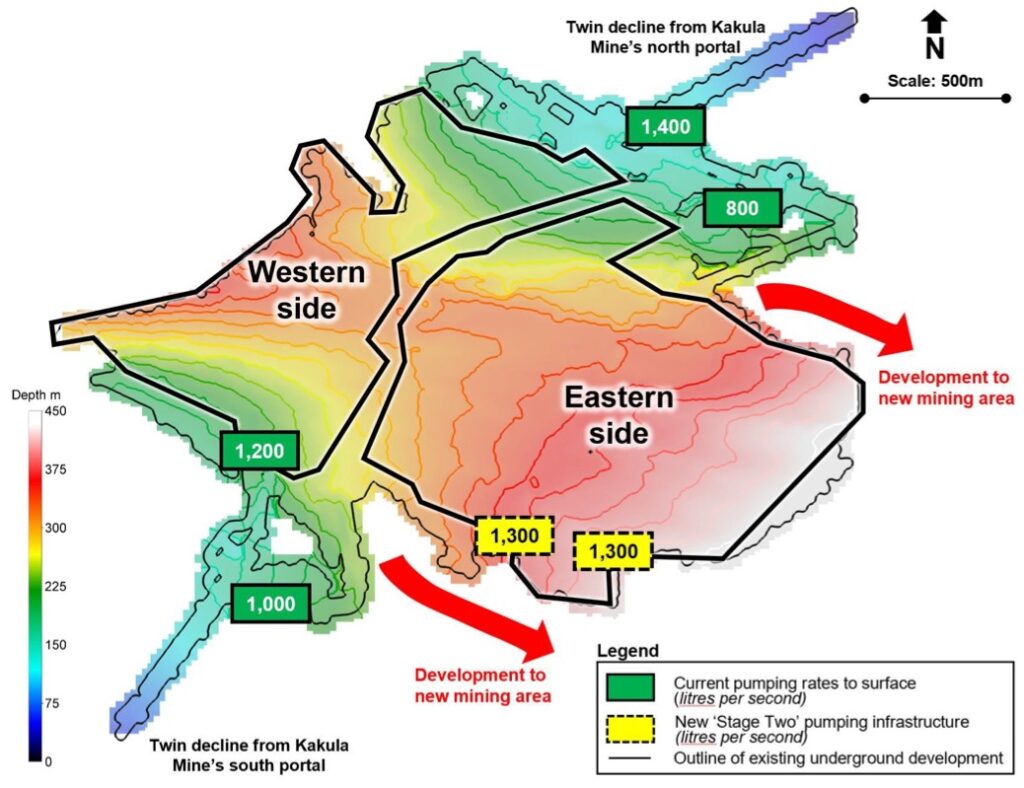

Although water inflow rates into the Kakula Mine modestly increased following the initial seismic activity, they have since stabilized at approximately 4,000 litres per second. With existing underground pumping infrastructure impacted by the seismic activity, a total of approximately 4,400 litres per second of additional underground pumping capacity was installed, stabilizing underground water levels. The new pump stations feed into the existing central pumping infrastructure, where the water is then pumped to surface at four locations near the bottom of the north and south twin declines, as shown in Figure 2.

With water levels stabilized, mining in the western side of the Kakula Mine has restarted. Mobile equipment and mining crews, which were evacuated from the mine on May 18, 2025, are returning underground, with the first blast having occurred on June 7, 2025. Short-term mine plans have been updated to include the recommendations from the preliminary geotechnical findings. Kamoa-Kakula’s mining crews aim to ramp up mining from the western side of the Kakula Mine to approximately 300,000 tonnes per month (3.6 million tonnes per year on an annualized basis) during the second half of 2025, subject to underground conditions.

For the remainder of 2025, Kakula’s underground mining crews will focus on three activities:

- ramping up mining on the western side of the Kakula Mine;

- developing a new mining area on the eastern side of the Kakula Mine;

- and ramping up production from the Kamoa mining area.

Figure 2: Overview of Kakula Mine’s existing underground infrastructure, showing current pumping rates, future pumping capacity and depth of mine workings.

The additional mining crews deployed to the Kamoa mining area, approximately 10 kilometres north of Kakula, will assist the existing teams with underground development, as well as decline development from the construction of a new box cut planned at the Kansoko Mine. The new box cut will enable increased production from Kansoko, providing an additional source of ore for the Phase 1 and Phase 2 concentrators.

Mining crews to focus on new mining area in eastern side of Kakula; development to commence imminently, isolated from dewatering activities

Mining in the eastern side of the Kakula Mine will follow a new mine plan, prioritizing development to a new mining area further east, beyond the existing mine workings. The new mining area will be separated from the existing mine workings by a barrier pillar. The barrier pillar is designed to protect the new mining area from any potential spread of geotechnical instability from the existing mining area.

Mining crews will construct two new access drives to the new mining area, which are expected to start imminently. The new access drives will be developed simultaneously, advancing east from existing underground infrastructure, as shown in Figure 2.

Development to the new mining area is expected to be conducted in both ore and waste and be completed in the second quarter of 2026. The new development drives will be isolated from the mine workings that being dewatered and will advance independently of dewatering activities.

Following the completion of dewatering activities on the eastern side of Kakula, a physical geotechnical inspection of the mine’s existing workings will be conducted, concluding the full assessment by the geotechnical experts. The results of this assessment will determine the approach and extent of mining in this area.

As shown in Figure 2, the mine workings are at their deepest on the eastern side of the mine and therefore underground flooding is predominantly concentrated around this area.

The Kamoa-Kakula engineering team has a two-stage plan to dewater the entire Kakula Mine.

Stage One involves the installation of additional temporary underground pumping infrastructure to stabilize and maintain current water levels. Stage One was completed as announced on June 2, 2025.

Stage Two involves the installation of high-capacity, submersible pumps, and new permanent infrastructure to fully dewater the entire Kakula Mine from surface. Kamoa Copper has ordered five high-capacity pumps, each rated at 650 litres per second. Additional pumps will also be ordered as part of the long-term pumping infrastructure plan. These pumps will be deployed in pairs down existing shaft infrastructure, accessing the deepest sections of the Kakula Mine as shown in Figure 2.

Dewatering activities are expected to commence in August 2025. Engineering crews will refurbish underground pumping and ventilation infrastructure, as well as complete geotechnical assessments, as water levels subside. Dewatering of the entire Kakula Mine is expected to be complete during the fourth quarter.

Looking south: The two existing shaft locations where the “Stage Two” dewatering surface pumping infrastructure will be installed to dewater the eastern side of the Kakula Mine. Water will be discharged into existing surface water channels (right of picture).

Looking north with the Phase 1 and 2 concentrators in the background: One of the two shaft locations shown in the foreground that will be used for the “Stage Two” dewatering of the deepest area of the Kakula Mine.

A high-capacity submersible pump, similar to those being procured by Kamoa Copper for dewatering the Kakula Mine, prior to being lowered down a shaft at the Luansha Copper Mine, Zambia in September 2024. Photo source: CNMC (China Nonferrous Metal Mining Group Co., Ltd).

Preliminary geotechnical findings on the cause of recent seismic activity

Two prominent, independent geotechnical engineering organizations, Beck Engineering of New South Wales, Australia (Beck Engineering) and Open House Management Solutions of Potchefstroom, South Africa (Open House), were engaged and mobilized to Kamoa-Kakula shortly after seismic activity was first detected on May 18, 2025. Both consulting engineering firms have been working diligently with Kamoa-Kakula’s engineering team, with support from Ivanhoe Mines.

Preliminary findings indicate that the seismic activity originated in an area within the eastern side of the Kakula Mine with a mature percentage of extraction. Current thinking postulates that blocks of ore, earmarked for secondary extraction, started to yield in a cascading fashion, which resulted in stress redistribution onto regional pillars. As a consequence, the regional pillars became over-stressed and started to yield. The backfill, placed in mined-out stopes, was not capable of preventing the stress redistribution onto regional support pillars, but may have been a mitigant. The possibility that adverse regional geological features may have exacerbated the yielding of regional pillars cannot be excluded at this time.

Pillars are sections of untouched ore or rock left in place to support the roof of the mine, while stopes are mined-out areas. Backfill is the process whereby mined-out stopes are filled with a mixture of concentrator tailings and cement, which cures to achieve a targeted strength.

The geotechnical assessment has not yet been finalized as it relies on physical access to the eastern section of the Kakula Mine once dewatering is completed.

The preliminary findings recommend modifying the short-term mine plans to increase pillar widths for additional structural support. The findings also advise changes to the mining sequence to improve stress distribution and overall stability. Furthermore, enhanced geotechnical monitoring will be installed throughout the mine.

Kamoa-Kakula’s management, together with Beck Engineering, Open House and other technical consultants, are evaluating any changes to the short-, medium- and long-term mine plans in light of these preliminary geotechnical findings.

Work on an updated life-of-mine integrated development plan, which was underway before the seismic activity occurred, has been paused until Ivanhoe Mines’ engineering team and its panel of technical experts have reviewed and agreed on any updated assumptions. Ivanhoe Mines will provide a timing update on the delivery of an updated IDP once work recommences.

Members of Kamoa-Kakula’s mining crew, (L-R) Kalume Malidja, Mining Foreman and Morné Du Plooy, Mining Superintendent

Phase 1 and 2 concentrators operating at reduced capacity and set to ramp up as mining restarts on western side of the Kakula Mine; Phase 3 concentrator continues to outperform

Crews recommenced mining on the western side of Kakula on June 7, 2025. Mining from this section will commence safely and conservatively, with planned ramp-up to an annualized mining rate of 3.6 million tonnes during the third quarter. This rate is sufficient for the Phase 1 and 2 concentrators to operate at a throughput of more than 80% of their combined design capacity of 9.2 million tonnes per annum, supplemented by ore from surface stockpiles and ore trucked from the Kamoa mines. Run-of-mine grade from the western side of Kakula, including development, is expected to range between 3.0% and 4.0% copper for the remainder of the year.

The Phase 1 and 2 concentrators continue to operate at approximately 50% of their combined capacity, processing ore from surface stockpiles since underground operations ceased on May 18, 2025.

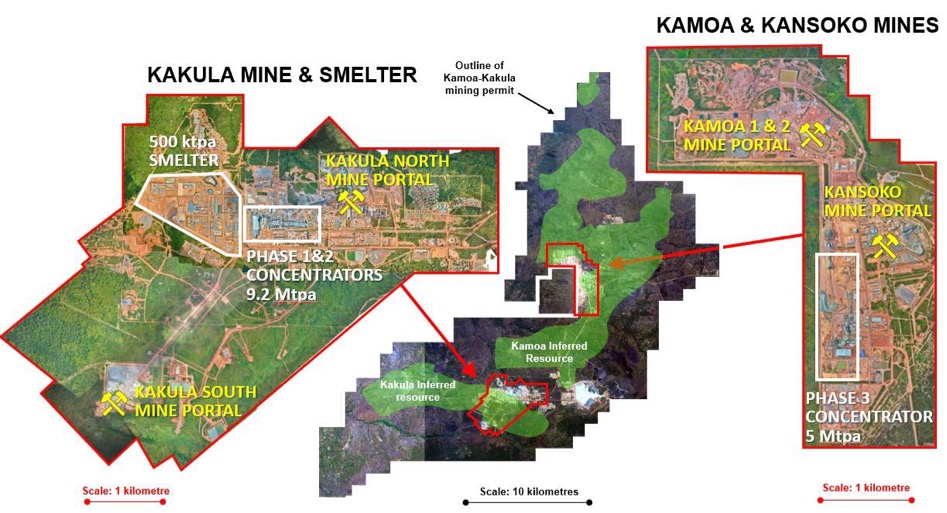

The Phase 3 concentrator, located adjacent to the Kamoa mines area as shown in Figure 3, has continued to outperform operationally since the start of the year. The concentrator is operating at an average annualized milling rate of approximately 6.5 million tonnes per annum, which is 30% higher than the concentrator’s design capacity of 5 million tonnes per annum. Year-to-date, ore processed by the Phase 3 concentrator has an average feed grade of 2.84% copper. Mining from the Kamoa 10 and Kansoko mines, have ramped up over the past 2 months to a combined rate of over 6.8 million tonnes per annum on an annualized basis.

Short-term mine plans for the Kamoa and Kansoko mines have findings been updated to include the recommendations from the preliminary geotechnical assessment. Longer-term mine plans will be also be reviewed alongside Kakula.

Figure 3. Overview of the Kamoa-Kakula Copper Complex

Revised 2025 production guidance Kamoa Copper

Updated 2025 production guidance is based on several assumptions and estimates as of June 10, 2025. The guidance provided involves estimates of known and unknown risks, uncertainties, and other factors that may cause the actual results to differ materially. The revised 2025 production guidance takes into account the probable effect of recent seismic activity and associated interruptions in mining operations at the Kakula Mine.

Although mining in the western side of the Kakula Mine has restarted risk factors remain, including it is too early to accurately predict potential disruption caused by further unexpected seismic activity, the integrity of underground infrastructure, the ability to ramp up underground operations, the ability to complete dewatering activities and the time required to access the new mining areas.

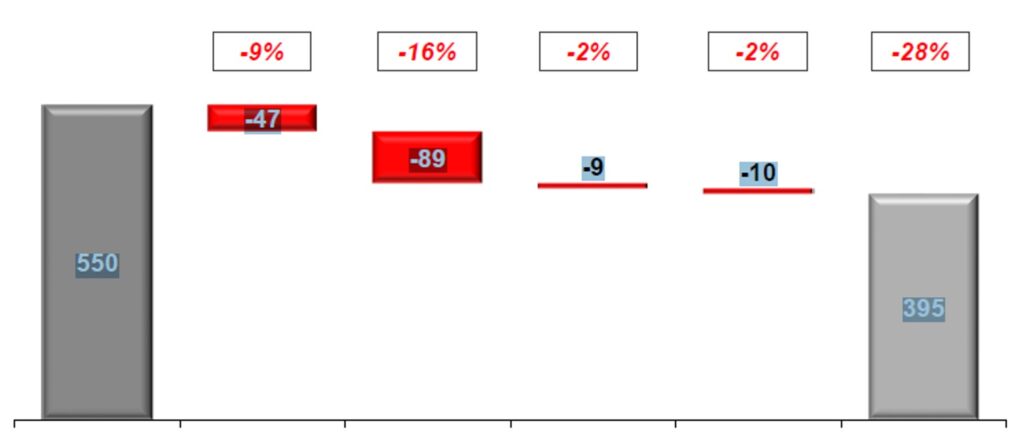

The updated 2025 production guidance is based on an assessment of these factors that management believes are reasonable at this time, given all available information. A waterfall diagram shown in Figure 4 details a breakdown of the revised production guidance.

Revised 2025 Production Guidance Kamoa-Kakul

370,000 – 420,000 Contained copper in concentrate (tonnes)

All figures are on a 100%-project basis and metal reported in concentrate is before refining losses or payability deductions associated with smelter terms. Figure 4. Waterfall breakdown of original to revised 2025 production guidance, approximated by category (‘000’s tonnes of copper)

| Previous guidance(mid-point) | Lower throughput (Phase 1&2) | Lower recovery (Phase 1&2) | Lower recovery (Phase 1&2) | Lower grade &recovery (Phase 3) | Revised guidance(mid-point) |

The waterfall chart in Figure 4 details the adjustments from the initial production forecast to the revised forecast, with the changes expressed in thousands of tonnes and as a percentage.

The 2026 target of approximately 600,000 tonnes of copper production is withdrawn pending further review. Ivanhoe Mines will provide a timely update on the 2026 target production rate when more information becomes available. Ivanhoe Mines will provide updated 2025 C1 cash cost (C1) per pound of payable copper in the second quarter of 2025 financial results.

On-site direct-to-blister smelter to start up in third quarter

Kamoa Copper’s Senior Management has confirmed that the start-up of the on-site direct-to-blister copper smelter will commence in early September 2025, with first anode expected in October. The smelter can operate at a minimum operating capacity of 50%, or approximately 250,000 tonnes of copper on an annualized basis.

As at May 31, 2025, unsold concentrate stockpiles consisted of 33,000 tonnes of copper. In preparation for the first feed of concentrate, approximately four to six weeks after start-up commences, it is expected that total unsold concentrate stockpiles will be approximately 35,000 tonnes of copper in concentrate.

In addition, Kamoa-Kakula’s senior management anticipates the commissioning of the 178-megawatt Turbine #5 at the Inga II hydroelectric dam in October 2025, further boosting domestically generated hydroelectricity supplied to the KamoaKakula Copper Complex.

Disclosure of technical information

Disclosures of a scientific or technical nature in this news release, other than the preliminary geotechnical findings and the technical information in Figure 1, have been reviewed and

approved by Steve Amos, who is considered, by virtue of his education, experience, and professional association, a Qualified Person under the terms of NI 43-101.

Mr. Amos is not considered independent under NI 43-101 as he is Ivanhoe Mines’ Executive Vice President, Projects. Mr. Amos has verified the technical data disclosed in this news release.

Disclosures of a scientific or technical nature regarding the preliminary geotechnical findings in this news release have been reviewed and approved by Koos Bosman, who is considered, by virtue of his education, experience, and professional association, a Qualified Person under the terms of NI 43-101.

Mr. Bosman is considered independent of the company for purposes of NI 43-101 as he is Managing Director of Open House. Mr. Bosman has verified the technical data regarding the preliminary geotechnical findings disclosed in this news release.

Disclosures of a scientific or technical nature in Figure 1 of this news release have been reviewed and approved by Joshua Chitambala, who is considered, by virtue of his education, experience, and professional association, a Qualified Person under the terms of NI 43-101.

Mr. Chitambala is not considered independent under NI 43-101 as he is the Resource Manager for Ivanhoe Mines. Mr. Chitambala has 13 verified the other technical data regarding the surface stockpiles disclosed in this news release.

About Kamoa Copper

The Kamoa Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%), and the Government of the Democratic Republic of the Congo (20%).

The Kamoa-Kakula Copper Complex is one of the world’s highest-grade and fastest-growing major copper mining operations. Copper concentrates were first produced in May 2021, and with the ongoing Phase 2 and Phase 3 expansions, Kamoa Copper is on track to become one of the largest copper-producing operations globally, with projected output for 2025 ranging between 520,000 and 580,000 tonnes of copper in concentrate.

The Kamoa Copper Complex is powered by clean, renewable hydroelectric energy and ranks among the world’s lowest greenhouse gas emitters per tonne of copper metal produced, based on Scope 1 and 2 emissions criteria.