Phase 1 and 2 concentrators now operating at approx. 85% of design capacity, including 45% ore feed from Kakula western side; Phase 3 concentrator operating 30% above design capacity

Construction of Project 95 is approximately 50% complete and on schedule for completion in Q1 2026

During the second quarter, Kamoa Copper Phase 1, 2, and 3 concentrators milled a total 3.62 million tonnes of ore, producing 112,009 tonnes of copper concentrate, representing an 11% year-on-year increase.

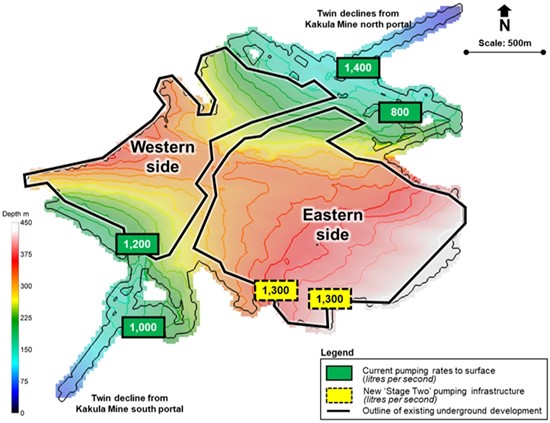

As previously guided, “Stage One” dewatering activities have been in place and operating to plan as of June 2, 2025. Water levels on the eastern side of the Kakula Mine have decreased modestly ahead of “Stage Two” dewatering activities from next month. The five, procured high-capacity, submersible “Stage Two” dewatering pumps are currently undergoing factory assembly in China and are expected to be air-freighted to site within the coming weeks.

In early June, mining on the western side of the Kakula mine restarted. By mid-June, the mining rate had ramped up to 300,000 tonnes per month (3.6 million tonnes on an annualized basis), with grades ranging from 3% to 4% copper.

As a result, since mid-June, the combined processing rate of the Phase 1 and 2 concentrators ramped up to approximately 670,000 tonnes per month (8 million tonnes per annum on an annualized basis).

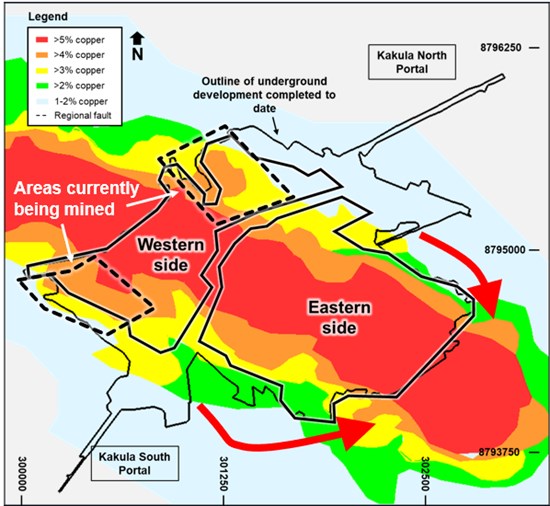

Underground development of a new mining area, located on the far eastern side of the Kakula Mine, has recently commenced. The development of the two new access drives will be conducted from existing underground infrastructure.

The heat-up of Kamoa-Kakula’s state-of-the-art, 500,000-tonne-per-annum direct-to-blister copper smelter is expected to start in September 2025, with the first production of 99.7%-pure copper anodes anticipated in October 2025.

Summary of quarterly production data from Kamoa Copper

| Q2 2024 | Q3 2024 | Q4 2024 | Q1 2025 | Q2 2025 | |

| Phase 1 & 2 | |||||

| Ore tonnes milled (000’s tonnes) | 2,288 | 2,215 | 2,329 | 2,211 | 1,991* |

| Feed grade of ore processed (% copper) | 5.04% | 4.86% | 5.08% | 5.01% | 4.12%* |

| Copper recovery (%) | 87.0% | 86.6% | 87.0% | 88.3% | 85.4%* |

| Ore tonnes milled (000’s tonnes) | 99,706 | 94,214 | 102,042 | 97,575 | 71,401* |

| Phase 3 | |||||

| Ore tonnes milled (000’s tonnes) | 93 | 1,050 | 1,326 | 1,512 | 1,631 |

| Feed grade of ore processed (% copper) | 1.67% | 2.64% | 2.82% | 2.76% | 2.92% |

| Copper recovery (%) | 83.3% | 79.9% | 85.1% | 85.1% | 85.5% |

| Copper in concentrate produced (tonnes) | 1,106 | 22,099 | 31,777 | 35,545 | 40,608 |

| Combined Phase 1, 2, and 3 | |||||

| Ore tonnes milled (000’s tonnes) | 2,381 | 3,266 | 3,655 | 3,723 | 3,622 |

| Feed grade of ore processed (% copper) | 4.91% | 4.14% | 4.26% | 4.10% | 3.58% |

| Copper recovery (%) | 86.9% | 85.3% | 86.6% | 87.4% | 85.4% |

| Copper in concentrate produced (tonnes) | 100,812 | 116,313 | 133,819 | 133,120 | 112,009 |

Data in bold denotes a quarterly record

*Phase 1 & 2 production in the second quarter was impacted by seismic activity at the Kakula Mine as announced on May 20, 2025.

Phase 1 and 2 concentrators are operating at approximately 85% capacity, with approximately 45% of feed coming from the western side of the Kakula Mine

Phase 1 and 2 concentrators are operating at approximately 85% capacity, with approximately 45% of feed coming from the western side of the Kakula Mine

During the second quarter, the Phase 1, 2, and 3 concentrators milled 3.62 million tonnes of ore, producing 112,009 tonnes of copper, representing an 11% year-on-year increase. Copper production for the first half of 2025 totaled 245,127 tonnes.

In June, Kamoa-Kakula’s Phase 1, 2, and 3 concentrators produced a total of 28,147 tonnes of copper. During the month, approximately 15,000 tonnes of copper were produced by the Phase 1 and 2 concentrators, at an average grade of 3.3% copper and an average recovery rate of 79%. The lower-than-average recovery rate is due to lower recoveries achieved from processing lower-grade ore from surface stockpiles.

The Phase 1 and 2 concentrators commenced the processing of ore from the western side of the Kakula Mine on June 8, 2025. Since mid-June, the Phase 1 and 2 concentrators ramped up to a combined processing rate of approximately 670,000 tonnes per month, or 8 million tonnes per annum on an annualized basis. It is expected that the Phase 1 and 2 concentrators will continue to process ore at this rate for the remainder of 2025, with a target of approximately 50% of ore feed coming from surface stockpiles and 50% from the western side of the Kakula Mine. The processing of surface stockpiles is expected to continue until they are depleted in Q1 2026.

As announced on June 11, 2025, mining operations on the western side of the Kakula Mine restarted on June 7, 2025. By mid-June, the mining rate had ramped up to 300,000 tonnes per month (3.6 million tonnes on an annualized basis). As previously guided, mining in the western side of the Kakula Mine will initially focus on higher-elevation areas in the north and southwest, as shown in Figure 1, where copper grades range between 3% and 4%. Mining of these areas will continue into the fourth quarter, until Stage Two dewatering of the eastern side of the Kakula Mine is well advanced. From late 2025, mining crews plan to advance deeper into the western side of the Kakula Mine, where copper grades are expected to increase to approximately 5%.

The Phase 3 concentrator milled a record 1,631 tonnes of ore in the second quarter, producing a record 40,608 tonnes of copper. The milling record is equivalent to an annualized rate of 6.5 million tonnes, which is 30% higher than the Phase 3 concentrator’s design capacity of 5.0 million tonnes per annum. The average quarterly feed grade for the Phase 3 concentrator was a record 2.92% copper. For the remainder of 2025, it is expected that the feed grade into the Phase 3 concentrator will average approximately 2.5% copper, as the cut-off grade is lowered to achieve a greater mining rate. Currently, all ore mined at the Kamoa and Kansoko mines is processed by the Phase 3 concentrator.

During the second half of 2025, the combined mining rate from the Kamoa and Kansoko mines will increase, with up to 100,000 tonnes per month of this ore fed into the Phase 1 and 2 concentrators, replacing a portion of the stockpile feed.

Stage One dewatering underway as planned; delivery of Stage Two dewatering pumps expected from next month

As previously guided, “Stage One” dewatering activities have been in place and operating to plan as of June 2, 2025. This has enabled the water levels on the eastern side of the Kakula Mine to decrease modestly, ahead of “Stage Two” dewatering activities which are expected to commence in August. In the meantime, the declining water levels have enabled mining crews to access additional areas and commence selective rehabilitation.

“Stage Two” dewatering involves the installation of high-capacity, submersible pumps and new permanent infrastructure to fully dewater the entire Kakula Mine from surface. Kamoa Copper has ordered five high-capacity pumps, each rated at 650 litres per second, from Hefei Hengda Jianghai Pump Co., Ltd. of Anhui Province, China. The pumps are currently undergoing factory assembly and are expected to be air freighted in August.

Looking north with the Phase 1 and 2 concentrators in the background, cranes and steel piping are mobilized to one of the two existing vertical shaft sites that will be used to dewater the eastern side of the Kakula Mine.

Concurrently, site preparation activities are advancing well. The high-capacity, submersible pumps will be installed in pairs down two adjacent shafts that access the deepest sections of the eastern side of the Kakula Mine, as shown in Figure 1. The remaining pump will be kept in reserve. The pumps will be connected to piping and lowered down the existing shafts from the surface. Discharged water from the submersible pumps will be fed into existing surface water channels that feed into on-site settling and treatment ponds.

The total capital cost of the Stage One and Stage Two dewatering activities, including the purchase, transport, and installation of the high-capacity, submersible dewatering pumps, is expected to be up to $70 million, including contingency.

Figure 1. An illustration of the Kakula Mine’s existing underground infrastructure as of June 2025, showing the depth profile of the western and eastern sections and existing (Stage One) and new (Stage Two) vertical pumping locations.

Development to the new mining area on the far eastern side of the Kakula Mine has commenced

A new mining area, located on the far eastern side of the Kakula Mine, as indicated by the red arrows in Figure 2, will be initially accessed via two new access drives. The mining crews commenced construction of the access drives in the past week.

Development of the new mining area is expected to be initially conducted in waste before entering ore from early 2026. Mining of the area is expected to commence in Q2 2026.

The new access drives will be developed simultaneously, advancing east from existing underground infrastructure. The new mining area will not require new mine access from the surface. The area will be accessed from existing underground infrastructure that is not affected by the ongoing dewatering activities.

Figure 2. An illustration of the Kakula Mine’s existing underground infrastructure, showing the grade profile and the location of the two access drives (red arrows) to the new eastern mining area.

Notes: Existing underground development as at June 2025. Illustration is based on the 2023 Kamoa-Kakula IDP showing the estimated average grade of each vertical stack of blocks above a 2% total copper cut-off. A minimum 6-metre thickness is applied.

Smelter heat-up scheduled to start in September; first copper anode production expected in October

As announced on June 11, 2025, Kamoa-Kakula’s senior management confirmed that the start-up of the on-site direct-to-blister copper smelter will commence in early September 2025, with the first production of anode expected in October. The smelter can operate at a minimum operating capacity of 50%, or approximately 250,000 tonnes of copper on an annualized basis. Kamoa-Kakula’s management team expects to prioritize the processing of all concentrates produced by the Phase 1, 2, and 3 concentrators through the on-site smelter, with any excess concentrate toll-treated at the nearby Lualaba Copper Smelter.

As at June 30, 2025, Kamoa-Kakula’s total on-site, unsold concentrate stockpiles consisted of 53,600 tonnes of copper, of which approximately 31,500 tonnes are stored on the smelter site. In preparation for the first feed of concentrate, approximately four to six weeks after start-up in early September, it is expected that total on-site, unsold concentrate stockpiles will be approximately 35,000 tonnes of copper in concentrate.

First copper anode production from Kamoa-Kakula’s state-of-the-art, on-site copper smelter is expected in October.

Project 95 is approximately 50% complete and on schedule for completion in Q1 2026

Kamoa-Kakula’s Project 95 is advancing well at 50% complete and is on schedule for completion in Q1 2026. The “Project 95” initiative for Phase 1 and 2 concentrators aims to increase the overall recovery rate to 95%, up from the design recovery rate of 87%, based on a high-grade feed of 5% copper.

Pendant la période intermédiaire, alors qu’une partie de la mine de Kakula est en cours de rénovation, une partie du minerai alimentant les concentrateurs des Phases 1 et 2, provenant des mines de Kakula et de Kamoa, sera de qualité inférieure. L’équipe d’ingénieurs de Kamoa-Kakula vise à maintenir un taux de récupération d’au moins 90 % à partir des sources de qualité inférieure.

Project 95 construction works are advancing well, as shown in the foreground, with the adjacent Phase 1 and 2 concentrator storage shed in the background.

Site clearance and early earthworks for Kamoa-Kakula’s 60-megawatt, on-site solar facility with battery storage have commenced

During late March and early April 2025, Kamoa Copper signed power purchase agreements (PPA) with CrossBoundary Energy DRC of Nairobi, Kenya, and La Societe Green World Energie SARL of Beijing, China, to provide up to 60 megawatts (MW) in baseload clean energy to Kamoa-Kakula’s operations from an on-site solar facility. The facilities, which will be owned, operated, and funded by CrossBoundary Energy and Green World Energie, will comprise a total of 406 MWp of Solar Photovoltaic (PV) capacity, with up to 1,107 MWh of battery energy storage (BESS). Kamoa Copper will be the sole off-taker of the electricity produced by both facilities.

Early construction works commenced in the second quarter with geotechnical surveying of the site, site clearing, and the ordering of long-lead items, including the BESS, E-house, and mounting structures.

Les premiers travaux de construction ont débuté au deuxième trimestre avec l’étude géotechnique du site, le défrichage et la commande d’éléments à long délai de livraison,

Construction completion is expected in mid-2026.

Site clearing and early earthworks are underway at Kamoa-Kakula’s 60 MW on-site solar (PV) facility, which is scheduled for completion in mid-2026.

Revised 2025 cash cost (C1) and capital expenditure guidance to be provided with Q2 2025 financial results; Kamoa Copper 2026 and 2027 production guidance to be provided in September

As announced on June 11, 2025, Kamoa Copper’s revised annual production guidance is 370,000 to 420,000 tonnes of copper. Ivanhoe Mines is expected to provide Kamoa-Kakula’s 2026 and 2027 copper production guidance in September, 2025.

It is expected that Kamoa Copper’s revised 2025 capital expenditure guidance will not exceed the upper end of the original 2025 guidance range of $1,420 to $1,670 million, as announced on January 8, 2025, on a 100% basis.

Offtake agreement signed for the remaining 20% of copper anode production from Kamoa-Kakula’s on-site smelter; offtake-linked advanced payment facility of $200 million also signed

As previously announced on January 8, 2025, CITIC Metal Limited and Gold Mountains International Mining Company Limited, a subsidiary of Zijin Mining, signed offtake agreements with Kamoa Copper for a combined 80% of the copper anode production from the Kamoa-Kakula smelter. The CITIC Metal and Gold Mountains anode offtake agreements also included offtake-linked advance payment facilities totalling $500 million. This facility was in addition to a $300 million Phase 3 concentrate offtake-linked advanced payment facility signed with both offtakers in 2024.

In June, an agreement for the remaining 20% of the smelter’s anode offtake was signed over a three-year term with Trafigura Asia Trading Pte Ltd. The offtake agreement with Trafigura also included a $200 million offtake-linked advance payment facility. The facility has an interest rate of the 1-month Secured Overnight Financing Rate (SOFR) plus 3.75%.

Also in June, Kamoa Copper’s existing $200 million loan facility with Standard Bank has been extended for a further 12 months on favourable terms. The funding arrangements will provide balance sheet flexibility in supporting the ongoing turnaround of the Kakula Mine.